Basic Industrial Automation

PLC is an industrial computer control system that continuously monitors the state of input devices and makes decisions based upon a custom program to control the state of output devices. Almost any production line, machine function, or process can be greatly enhanced using this type of control system. The biggest benefit in using a PLC is the ability to change and replicate the operation or process while collecting and communicating vital information. Allen Bradley, seimens

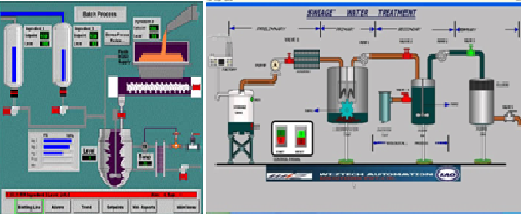

Supervisory control and data acquisition, a computer system for gathering and analyzing real time data. SCADA systems are used to monitor and control a plant or equipment in industries such as telecommunications, water and waste control, energy, oil and gas refining and transportation. SCADA systems were first used in the 1960s and are now an integral component in virtually all industrial plant and production facilities RS View 32.

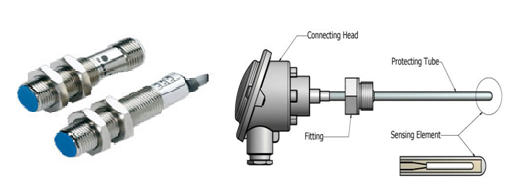

Field instruments are devices that measures a physical quantity such as flow, temperature, level, distance, angle, or pressure. Instruments are often part of a control system in refineries, factories, and vehicles. The control of processes is one of the main branches of applied instrumentation. Instruments attached to a control system may provide signals used to operate solenoids, valves, regulators,circuit breakers or relays.etc. These devices control a desired output variable, and provide either remote or automated control capabilities. Digital Sensor, Analog Sensor, RTD.

Control panel is a cabinet which contains electrical components to control various types of devices. Components include contactors, relays, circuit breakers, fuses, isolators, indication lamps, selector switches, push buttons, transformers, overload relays, timers etc. Control panels are used in all production lines Such as in factories to monitor and control machines or production lines. Older control panels are most often equipped with push buttons and analog instruments, whereas today in many cases HMI are used for monitoring and control purposes.

DC power supply provides the required level of DC power to the load using an AC supply at the input. Input transformer is used to transform the incoming line voltage down to the required level for the power supply. Typically the input transformer provides a step down function. The advantage of the DC supply is greater efficiency because the switching transistor dissipates little power when acting as a switch. Other advantages include smaller size and lighter weight from the elimination of heavy line-frequency transformers, and lower heat generation due to higher efficiency

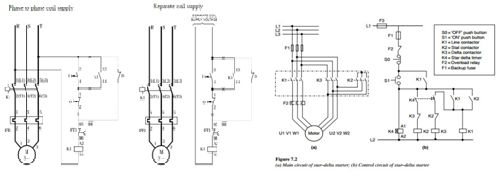

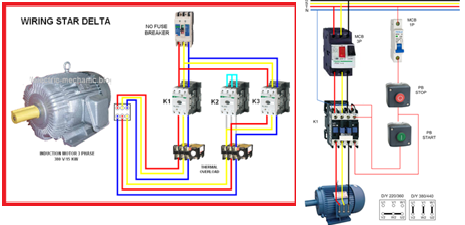

An electric motor is an electrical machine that converts electrical energy into mechanical energy. The reverse of this is the conversion of mechanical energy into electrical energy and is done by an electric generator, which has much in common with a motor.

An HMI is a software application that presents information to an operator or user about the state of a process, and to accept and implement the operators control instructions. Typically information is displayed in a graphic format. Human machine interfaces vary widely, from control panels for nuclear power plants to the screen and input buttons on a cell phone. A human user needs some way to tell the machine what to do, to make requests of the machine, or to adjust the machine. All of these devices can be utilized to send commands to a system or even an interlinked set of systems.PV 300 .

Basic Electrical & Electronics / Relay

In this part we discuss the electrical links required for operating automation equipment.These usually involve two categories: - High current links connecting the power components between the mains supply and the load.We shall not be dealing with this topic here but refer the reader to the sections on power supply and implementation. - Low current links connecting all the capture, dialogue, processing and power control components with the machine and process environment.

Basic Electrical & Electronics / Contactor

A contactor is an electrically controlled switch (relay) used for switching an electrical power circuit. Acontactor is typically controlled by a circuit which has a much lower power level than the switched circuit, such as a 24-volt coil electromagnet controlling a 230-volt motor switch.

A contactor is an electrically controlled switch (relay) used for switching an electrical power circuit. Acontactor is typically controlled by a circuit which has a much lower power level than the switched circuit, such as a 24-volt coil electromagnet controlling a 230-volt motor switch.

In this part we discuss the electrical links required for operating automation equipment.These usually involve two categories: - High current links connecting the power components between the mains supply and the load.We shall not be dealing with this topic here but refer the reader to the sections on power supply and implementation. - Low current links connecting all the capture, dialogue, processing and power control components with the machine and process environment.

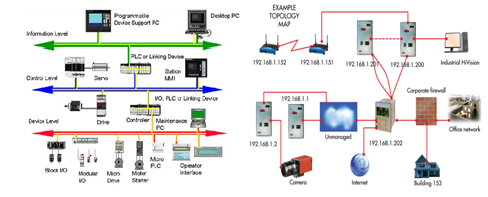

In this part we discuss the electrical links required for operating automation equipment.These usually involve two categories: - High current links connecting the power components between the mains supply and the load.We shall not be dealing with this topic here but refer the reader to the sections on power supply and implementation. - Low current links connecting all the capture, dialogue, processing and power control components with the machine and process environment.Rs 232, DH 485,Ethernet.

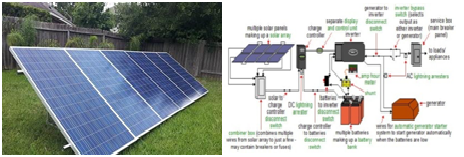

Photovoltaic solar panels absorb sunlight as a source of energy to generate electricity. A photovoltaic (PV) module is a packaged, connected assembly of typically 6x10 photovoltaic solar cells. Photovoltaic modules constitute the photovoltaic array of a photovoltaic system that generates and supplies solar electricity in commercial and residential applications 20 w ,50 w

A distributed control system (DCS) is a computerised control system for a process or plant usually with a large number of control loops, in which autonomous controllers are distributed throughout the system, but there is central operator supervisory control. This is in contrast to non-distributed control systems that use centralised controllers; either discrete controllers located at a central control room or within a central computer. The DCS concept increases reliability and reduces installation costs by localising control functions near the process plant, with remote monitoringand supervision.